Stability Chamber Suppliers: Key Factors To Evaluate Before Choosing The Right Partner

The choice of the appropriate top Stability Chamber Suppliers in India is not a decision to make but a long run investment to formulate precision, adherence and spouse faith. The growth of the industries such as pharmaceutical, food processing, cosmetics and biotechnology industries has increasingly become quality sensitive and stability chambers have become necessitated to be precise and reliable.

These chambers are important in ensuring that the temperature and humidity conditions are controlled to determine the shelf life, performance and durability of the products and selection of suppliers is a mission critical decision.

The Importance of Selecting The Correct Supplier of Stability Chamber

Long-term, intermediate and accelerated testing is carried out in a stability chamber. Any variation in temperature or humidity may lead to significant results. Weak or wrongly calibrated chambers may cause wrong test data that will affect product approvals, compliance and even brand image.

A reliable supplier ensures:

- • No changes in the environment.

- • Intelligent sensors and homogenous airflow to rely on.

- • Adherence of WHO, GMP and FDA requirements.

- • Effective after sales service to ensure operational downtime.

- • Low cost maintenance and durability of components.

In a business where accuracy cannot be compromised, quality control is in the selection of a reliable supplier.

1. Assess the Build Standards and Quality of Engineering

The design of stability chambers is supposed to be in durable materials and smart air distributive mechanisms. Modern chambers now use:

- • Corrosion resistance interiors made of stainless steel.

- • Thermal-stability high-density insulation.

- • Fridge Systems with high efficiency in regard to energy consumption.

- • Smart PID controllers to make an accurate adjustment.

The most consistent, over the years of operation, performance is provided by the suppliers who observe the highest QA procedures and utilize the industry-approved components.

2. Monitoring and the Obedience Alignment

A reliable supplier should be able to supply chambers that conform to key standards in the international level. The design and validation of products should be done based on the following:

- • World Health Organization Technical Report Series (TRS).

- • GMP Compliance.

- • FDA 21 CFR Part 11 for data logging.

Don’t take chances when it comes to audit: compliance minimizes audit risk and helps prepare your products to compete in the global marketplace.

3. Evaluate Technology, Controls and Monitoring Features

Modern state-of-the-art stability chambers are equipped with computerized monitoring device, cloud data documentation and automatic sensors. During the selection of a supplier, consider whether they provide:

- • Touchscreen PLC or HMI controllers.

- • Specific humidity and temperature programming.

- • Real time USB/Ethernet based data base logging.

- • Deviation alarm notifications.

- • Remote monitoring options.

The features minimize the use of manual intervention and guarantee accuracy during long test durations.

4. Research after Sales Service and Technical Support

Service support is one of the factors that have been left out. Your supplier must deliver:

- • Quick on-site service.

- • Calibration visits i.e. after every period.

- • Availability of spare parts.

- • Installation and validation technical instructions.

A well supported vendor means ease of functioning throughout the life of the equipment.

5. Relate Knowledge and Business Track Record

Established suppliers know what is required in controlled industries. They are reliable as seen in their track record, client portfolio and successful installations. Look for:

- • Years of experience.

- • Industry segments served.

- • R&D capabilities.

- • Customer testimonials.

- • A reputable supplier is not a simple vendor of equipment, he is a long-term partner.

6. Pricing vs. Value: The Total Cost of Ownership

The lowest cost is usually the one that causes long term operation costs. Instead, evaluate:

- • Product durability.

- • Energy efficiency.

- • Warranty period.

- • Calibration services.

- • Maintenance requirements.

A chamber that is initially pricier might prove to be better in the long run.

Rapid Comparison Checklist in Selecting a Supplier of Stability Chamber

| Factor of evaluation | What to evaluate? | Why it is important? |

| Construction, Insulation, Ventilation | Good Material, Insulation, Airflow | Long Test Accuracy |

| Compliance | ICH, WHO, GMP | Less audit and regulatory risks |

| Technology | Controllers, Data Logs | Ensures better precision and automation |

| After Sales Support | Service Availability | Reduces downtime |

| Experience | Industry Portfolio | Reliability and trust are indicated |

| Cost Effectiveness | Future Value | Saving future costs |

Conclusion

The right Stability Chamber Suppliers in India are critical in maintaining uniform product quality and regulatory legislation in all industries. Through a comprehensive assessment of engineering standards, compliance preparedness, technology capabilities and services in the long term, businesses can make a very favorable and confident decision. Coslab India with its accuracy constructed chambers and a good experience of the industry is a reliable partner that companies can turn to when they need reliable stability testing solutions.

FAQs

Q1. Can the stability chambers be tailor made?

Ans. The majority of the suppliers can customize in terms of size, sensors, shelving and control systems according to industry requirements.

Q2. What is the average stability chamber time?

Ans. A well-maintained chamber of worthy superiority can be used in a lifetime of 8-12 years without important problems.

Q3. Are steadiness chambers familiar on a regular basis?

Ans. Yes, the annual recalibration is suggested, to preserve the correct and consistent performance.

Q4. What is the significance of stability chambers in testing the product?

Ans. They assist companies with the verification of the behavior of a particular product under the conditions of temperature and humidity variations to guarantee long-term reliability.

How Education Lab Equipment Suppliers Support Modern Science Learning?

View More

How The Best Laboratory Equipment Suppliers Ensure Accuracy, Safety & Innovation?

View More

Stability Chamber Suppliers: Key Factors To Evaluate Before Choosing The Right Partner

View More

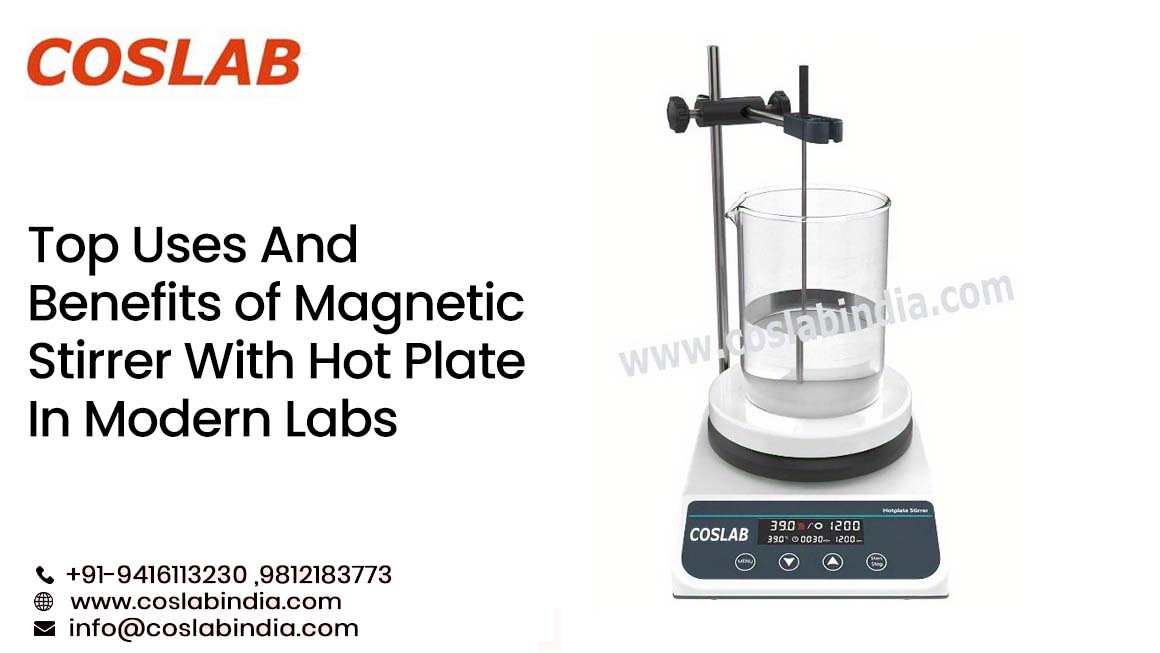

Top Uses And Benefits of Magnetic Stirrer With Hot Plate In Modern Labs

View More

Subscribe To Our Newsletter

Stay in touch with us to get latest news and discount coupons